WearShareyour brand proudly.

Get Quality Custom Apparel Locally and Affordably.

Welcome to Lab Seven.

Founded in 2006, now with 6 front-range locations – We've been helping local businesses, schools, and churches successfully market their brands in style for nearly 15 years.

Like you, we understand the challenges of standing out in a busy and competitive market.

That's why we believe:

You deserve quality apparel that reflects the legitimacy of your brand.

Get StartedYour plan for awesome apparel:

Pick your products

Fill out the size breakdown

Upload your logo idea

That's it!

We'll send you a no-commitment proposal, complete with pricing, product recommendations, and digital mockups!

Real world

marketing solutions.

Monetize Your Brand

Apparel sales offer your customers a fun and affordable way to show their support, while creating a new source of income for your business.

Connect With Your Crowd

Build positive relationships with your most important team members and clientele. One T-shirt at a time!

Outfit Employees in Style

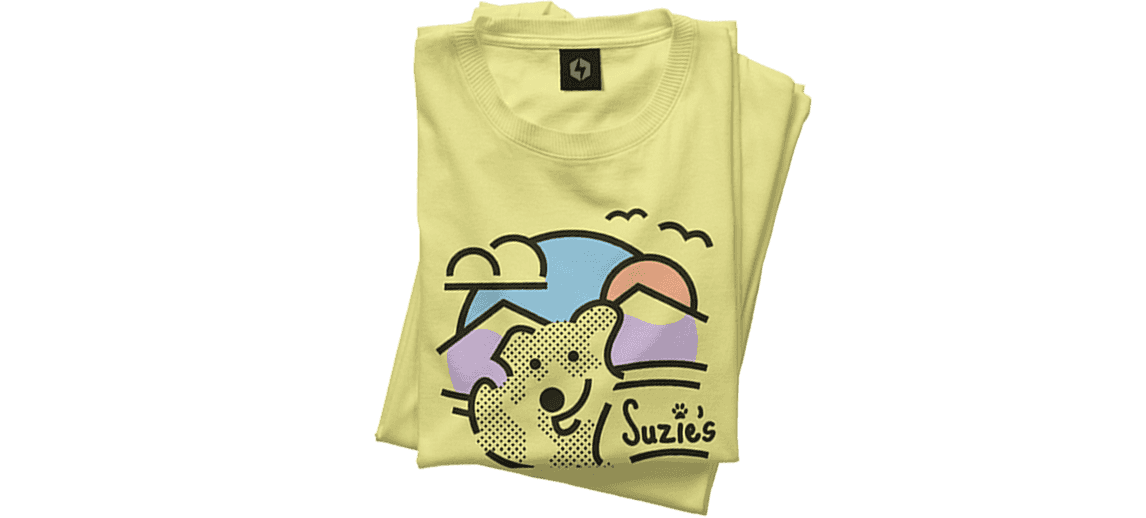

Affordable t-shirts no longer have to feel cheap. Outfitting your team with trendy, retail-quality styles goes a long way in representing your brand.

What does your business need?

Design Your Own Shirt

What Lab Seven Customers are Saying:

Casey Kent

Casey KentWe cannot say enough positive things about this company and their team. Nick has been amazing to work with, with fast response time, great ideas, superior accommodation and SUPER SOFT t-shirts with impeccable quality. We are return clients as their products are in their own category. Our family would highly recommend using Lab Seven for your future projects.

Bryan Coy

Bryan CoyI have been a customer here for a couple of years now and I cannot say enough about this fantastic team! They are always fair and competitive on price, timely, and the best quality around. You are definitely dealing with the best of the best when you hire this company for whatever your needs are!

Lenae Myers

Lenae MyersCould not have asked for a better company to work with to bring our company creative to life. Nick and his team were so helpful throughout the ordering process and provided great guidance. Our team couldn't be more happy on the high quality outcome! Looking forward to working with them in the future.

Kevon Fiedler

Kevon FiedlerHappy to say that we have found our permanent supplier for our apparel company! From the initial phone call to the design process, to the end results, we are highly satisfied! The team over at the Lakeside location has been awesome!

Barb Silverstein

Barb SilversteinI worked with Lab Seven to get school t-shirts and basketball jerseys printed for our elementary school. Everyone that I've interacted with there is very friendly and responsive to my questions. It was nice to go to the store and feel the quality of the t-shirt material before selecting the product. We've now gone back for our second year and intend to continue returning for our t-shirt and branding needs!!

Stop wasting your marketing budget on throwaway apparel.

Get t-shirts you'll want to wear.